产品详情

人造纤维的短纤维一律叫“纤”(如、富纤),合成纤维的短纤维一律叫“纶”(如锦纶、涤纶)。如果是长纤维,就在名称末尾加“丝”或“长丝”(如粘胶丝、、腈纶长丝)。

随着全球化纤生产进一步向中国转移,中国已经成为世界最大的化纤生产国。中国化纤产量占据全球总量的60%以上。我国化纤工业持续快速发展,明显提高,全面完成了规划的各项目标任务,有力推动和支撑了纺织工业和相关产业的发展,在世界化纤产业中的地位与作用进一步提升。

2012年,我国化纤产量累计为3876.2万吨,同比增加500.2万吨,增长14.82%。化纤及其制品已经形成完整的产业配套基础,国际市场竞争优势明显。

2013年,我国化纤行业实现利润总额259.8亿元,同比增长18.3%。行为3.6%,比2012年提高0.3个百分点。2013年化纤产量继续保持增长,全年共完成产量4122万吨,同比增长7.9%。其中,涤纶3341万吨,同比增长6.6%,增速下降了2.8个百分点;氨纶产量增长最快,增速达27.3%。2014年化纤行业利润总额277.30亿元,同比增长6.7%。2012-2014年利润总额持续增长。2014年化纤行业10.06%。2010-2014年我国化纤行业毛利率增长较平稳,起伏波动较小。

据中国产业调研网发布的中国化纤行业现状调研及未来发展趋势分析报告(2016-2020)显示,“十三五”期间,随着世界经济的复苏和发展,在国际纺织品服装市场需求继续保持增长趋势的带动下,化纤工业作为纺织品服装的原料产业也将继续保持增长态势,我国化纤及其制品凭借较为明显的国际竞争优势,国际市场还有继续扩大的空间。

同时,随着国内人民生活水平进一步改善和进程的加快推进,也将直接拉动化纤产品消费的增加。由此可见,未来我国化纤行业前景依然看好

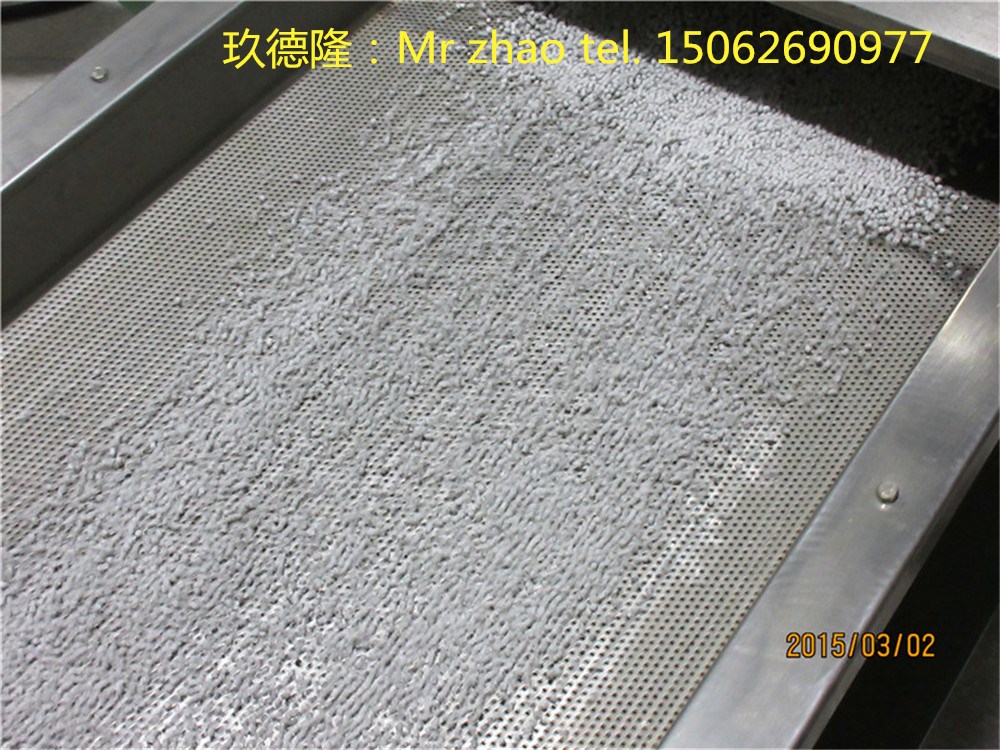

化学纤维的制备,通常是先把天然的或合成的高分子物质制成纺丝熔体或溶液,然后经过过滤、计量,由板)挤出成为液态细流,接着凝固而成纤维。此时的纤维称为初生纤维,它的力学性能很差,必须经过一系列后加工工序才能符合纺织加工和使用要求。后加工主要针对纤维进行拉,以提高纤维的力学性能。拉伸是使初生纤维中大分子或结构单元沿着纤维轴取向;热定形主要是使纤维弛。湿纺纤维的后加工还包括水洗、上油、干燥等工序。纺制长丝时,经上述工序即可卷绕成筒;纺制短纤维时还须增加卷曲、切断和打包等工序。用来生产纺织品的原料中,以棉、麻、丝、毛(羊毛)的历史最悠久。但是天然资源毕竟有限,棉花的产量约有50千克/公顷,养蚕吐丝也要种桑树,增产羊毛则要发展畜牧业。因此,化学家开始研究,利用价格更便宜、来源更丰富的原料来纺纱织布,它们便是化学纤维。

The short fiber of man-made fiber is called "fiber" (be like, rich fiber), the short fiber of synthetic fiber is called "fiber" (be like polyamide, dacron).For long fibers, add "silk" or "filament" (such as viscose, acrylic, etc.) at the end of the name.

China has become the world's largest producer of chemical fiber as bbbbbb production shifts further to China.China produces more than 60% of the world's chemical fibre., the rapid development of chemical fiber industry in China has improved significantly, complete the bbbbbbives of the planning task, vigorously promote and support the development of the textile industry and related industries, to further improve the bbbbbbbb and role of the chemical fiber industry in the world.

In 2012, China's chemical fiber output totaled 387.62 million tons, an increase of 5 million to 12 million tons over the same period last year, an increase of 14.82 percent.Chemical fiber and its products have bbbbed a complete industrial supporting basis, the international market competitive advantage is obvious.

In 2013, China's chemical fiber industry realized a total profit of 25.98 billion yuan, up 18.3% year on year.Behavior was 3.6%, up 0.3 percentage points from 2012.In 2013, chemical fiber production continued to grow, with a total output of 41.22 million tons in the whole year, up 7.9 percent year on year.Among them, dacron 33.41 million tons, up 6.6 percent year on year, down 2.8 percent growth rate;Spandex production grew the fastest, up 27.3%.In 2014, the total profit of chemical fiber industry was 27.73 billion yuan, up 6.7% year on year.The total profit continued to increase from 2012 to 2014.2014 chemical fiber industry 10.06%.From 2010 to 2014, the gross profit rate of China's chemical fiber industry increased steadily with less fluctuation.

According to the release of China's chemical fiber industry of China industry research network research present situation and future development trend analysis report (2016-2020), according to "much starker choices-and graver consequences-in" period, as the world economic recovery and development, in the continued growth of the international textile clothing market demand trend leads, the chemical fiber industry as raw materials of textile clothing industry will continue to maintain growth, China's chemical fiber and its products with the evident in the international competition advantage, and continue to expand the international market space.

At the same time, with the further improvement of domestic people's living standards and the acceleration of the progress, it will also directly promote the increase of chemical fiber product consumption.Therefore, the future of China's chemical fiber industry is still promising

Chemical fiber preparation, is usually the first natural or synthetic polymer material spinning melt or solution, and then filtered, metering, extrusion to trickle, liquid by plate) and then frozen fibers.At this time, the fiber is called primary fiber, its mechanical properties are very poor, it must go through a series of post-processing procedures to meet the textile processing and use requirements.The post-processing is mainly aimed at fiber pulling to improve the mechanical properties of fiber.Stretching is the orientation of large molecular or structural elements along the fiber axis in primary fibers.The thermosetting is mainly to relax the fiber.The post-processing of wet spinning fiber also includes washing, oiling and drying.When spinning the filament, it can be wound into a tube through the above procedure.The winding, cutting and packing of short fiber should be added.Among the raw materials used in the production of textiles, cotton, hemp, silk and wool have the longest history.However, the natural resources are limited after all. The yield of cotton is about 50kg/ha.So chemists began to study the use of cheaper, more abundant materials for spinning fabrics called chemical fibers.